German multinational corporation, who ran the Odeon and Parlophone labels. It traces it’s origins to a grammophone factory funded in 1896 by the Swedish inventor Carl Olef Lindström, who sold his fonographs and grammophones under the names Lyraphon and Lynophon.

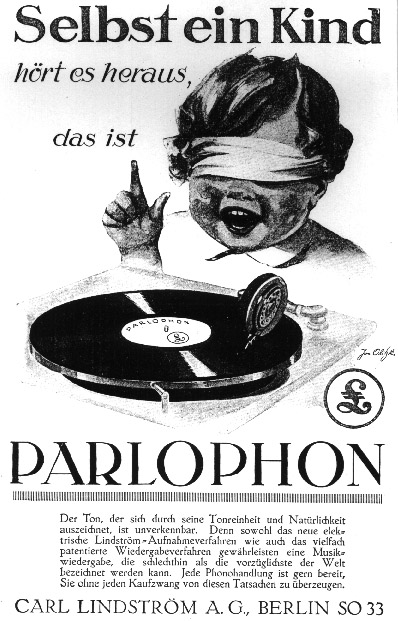

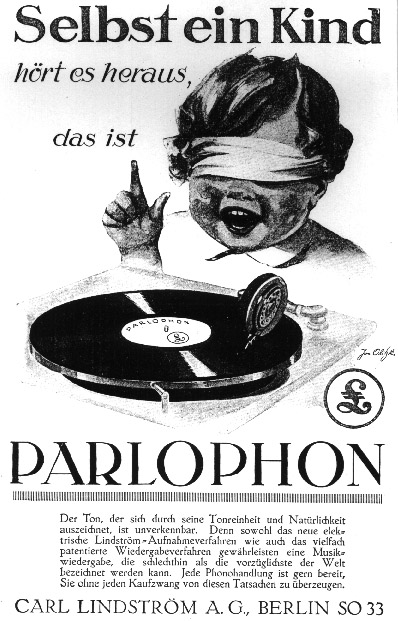

In 1904 Lindström sold his workshop to engineers Max Straus and Heinrich Zuntz of Salon Kinematograph Co. GmbH, company founded in 1902 that sold Lindström grammophones under the name Parlophon (now Parlophone). While the pair became the company’s directors, Lindström was retained as chief engineer and designer. The companies were merged to form Carl Lindström G.m.b.H. ; In 1906 Zuntz died and was replaced by Otto Heinemann, his brother in law. The company went public as Carl Lindström A.-G. in 1908 in order to raise more capital. By 1906 it had already sold 150000 grammophone machines.

Lindström was exclusively a grammophone manufacturing and sales company until 1910 when the first Parlophon records hit the market in Germany. Backed by the inmense success of his grammohpones, Lindström initiated an agressive expansion program:

Through 1910 to 1914, the company adquired the local German and European companies BeKa-Record A.-G. in 1910, International Talking Machine Co. m.b.H. turning it’s factory into the Odeon Werke, Società Italiana Di Fonotipia & it’s UK branch Fonotipia Co. Ltd. in 1911, Dacapo-Record Company M.B.H., Lyrophon-Werke GmbH in 1912 and Favorite Record A.-G. (previously Favorite GmbH) in 1913.

The final tally of labels by 1914 was Parlophon, Beka-Grand-Record, Era Grand Record, Era, Scala-Record, Odeon, Fonotipia, Jumbo-Record, Jumbola, Dacapo-Record, Lyrophon, Atlanta & Favorite.

The British branch was formed in 1923 as “Parlophone Records” which developed a reputation in the 1920s as a leading jazz label. In 1926, Columbia Graphophone Company acquired the Parlophone business, label name and its titles. Columbia Graphophone later became Columbia Records, and then EMI. The label’s fortunes began to rise in 1962, when George Martin signed rising new Liverpool band The Beatles. Along with fellow NEMS stablemates Cilla Black, Billy J. Kramer and the Fourmost, and contemporary Mancunian band The Hollies, The Beatles turned Parlophone into one of the world’s most famous and prestigious record labels.

EMI manufactured records at factory at Hayes in Middlesex, a town in London Borough of Hillington located near Heathrow Airport. The Hayes factory began pressing 45-rpm singles and 33 1/3-rpm long-playing vinyl records in October 1952. The pressing machines used by EMI at Hayes at the time the Beatles first signed with Parlophone were built by the Cramophone Company in the thirties. During the early sixties, EMI had approximately 120 presses. If all the machines were running, the factory could manufacture approximately 120,000 records a day. Although some factories changed stampers after press run of as little as 300 records, EMI did not change stampers that frequently. Stampers would be replaced when they were no longer capable of producing a quality-sounding disc. During the sixties, EMI cut the lacquers for Beatles singles, albums and EP on Scully lathes at Abbey Road. Lacquers were used to create the metal parts needed for manufacturing records. Each side of the record has its own set of metal parts. The basic procedure has been in use for over one hundred years with only minor changes. EMI made its metal parts at its Hayes factory.

The soft master known as a “Lacquer” would then be electroplated with a metal, commonly a nickel alloy (this and all subsequent metal copies were known as “matrices” or singular “matrix”). When this metal was removed from the Lacquer, it was a copy of the Lacquer and of the yet to be produced record. In the UK, the copy from the lacquer was called the “Master”. In the earliest days the Master was used as a mold to press records sold to the public, but as demand for mass production of records grew, another step was added to the process.

The metal Master was then electroplated to create “Mothers”. From the “Mothers”, “Stampers” would be formed. The Stampers would be used in hydraulic presses to mould the LP discs. The advantages of this system over the earlier more direct system included ability to make a large number of records quickly by using multiple stampers. Also, more records could be produced from each Master since molds would eventually wear out.

Since the Master was the unique source made to ultimately produce the Stampers, it was considered a Library Item. The “Pedigree” of any record can be traced through the Mother/Stamper identities used, by reading the lettering found on the record run-out area.

RDF URL

RDF URL